Minneapolis Duct Blaster® System (with DG-700)

(Please note that the DG-700 Pressure and Flow Gauge has been discontinued as of November 1, 2017. We will continue to recalibrate the DG-700. We expect to continue to repair the DG-700 for at least 5 years. All systems now come with a DG-1000 Pressure and Flow Gauge.)

System Includes

- Series B Duct Blaster® Fan

- DG-700 Pressure and Flow Gauge (10 – 1,500 CFM)

- Duct Blaster fan speed controller

- Three flow rings (optional Ring 4)

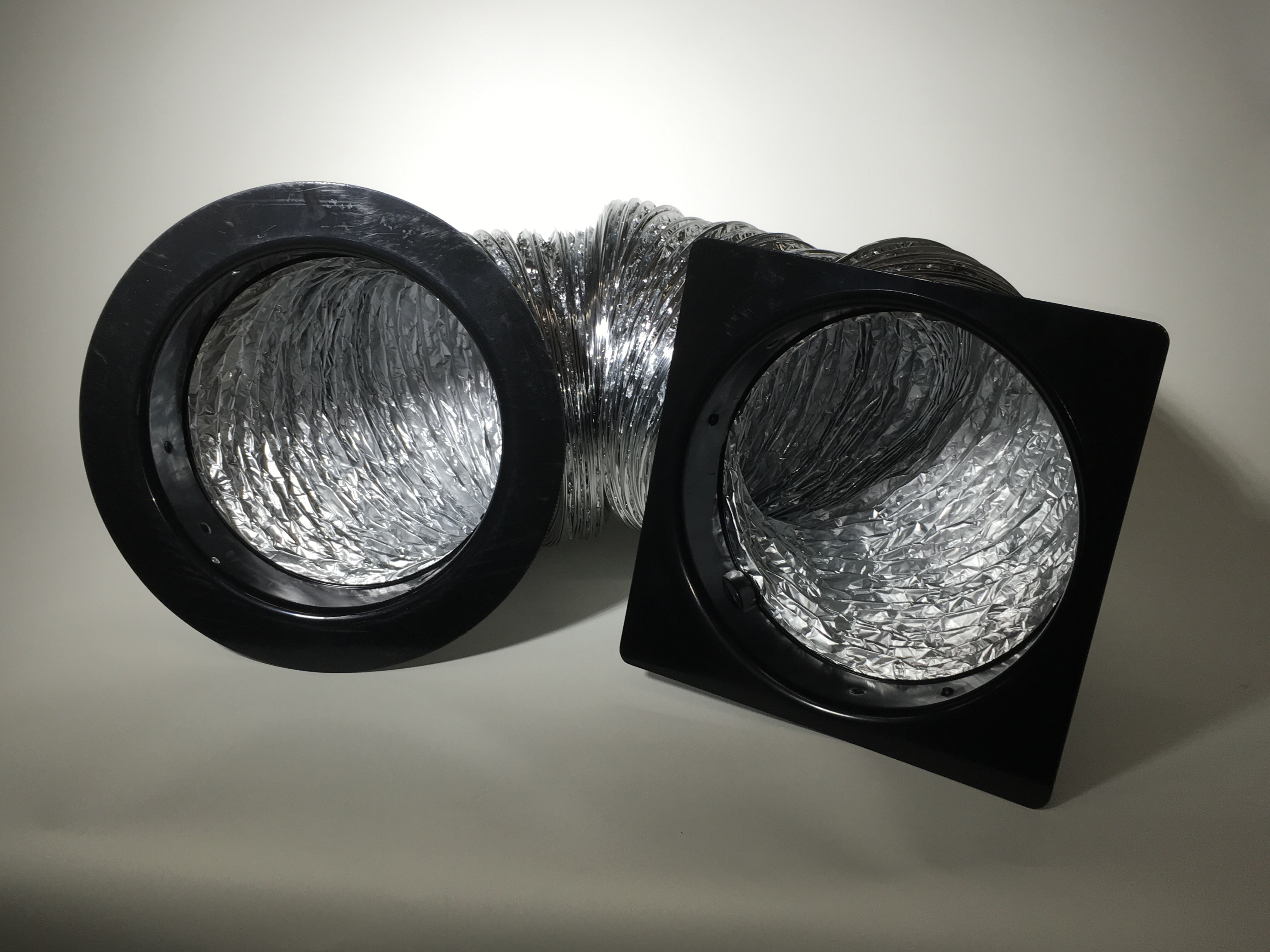

- Twelve feet of 10″ diameter flex duct

- Padded nylon carrying case

- Static pressure probe

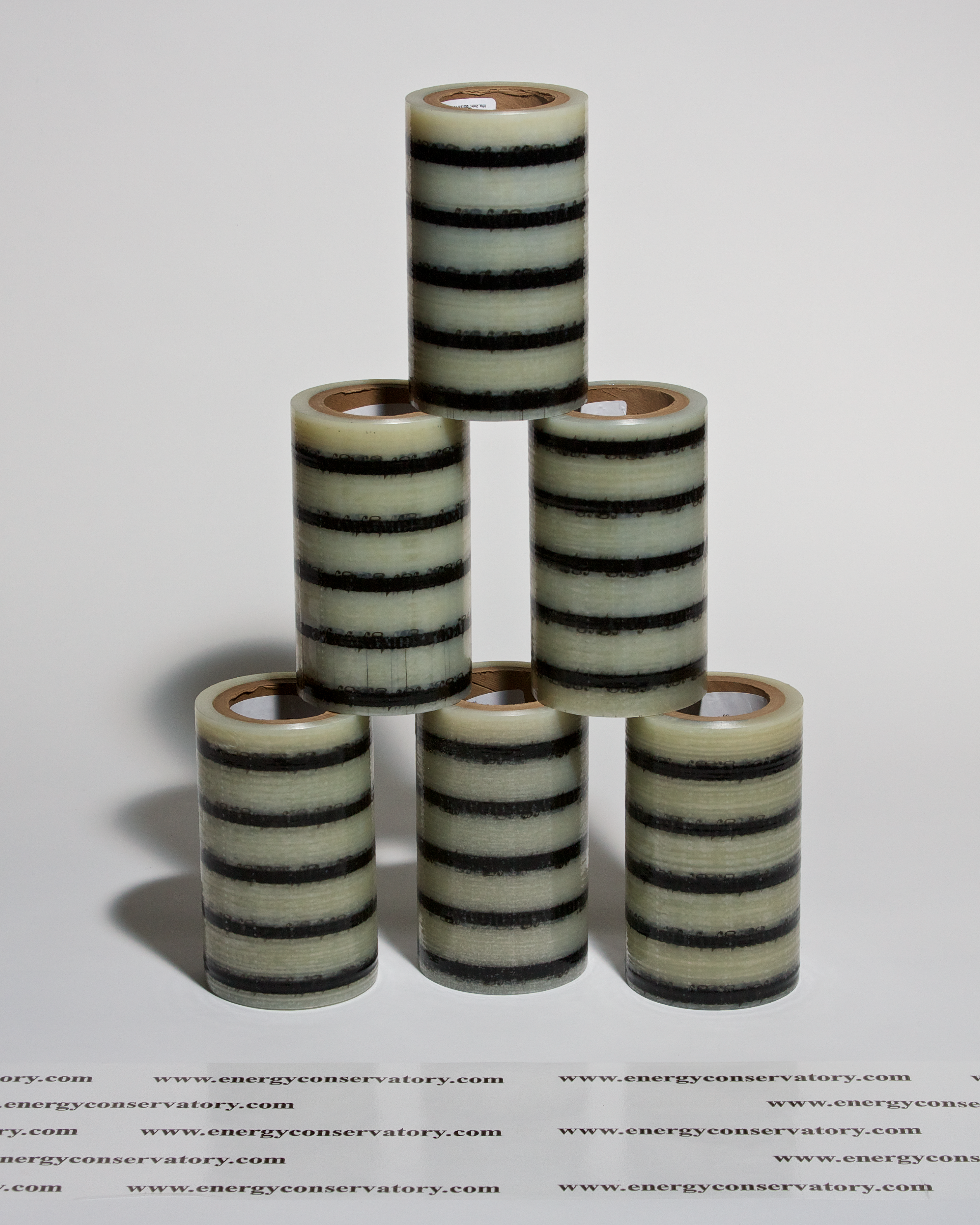

- Sample roll of Premium DuctMask Temporary Register Sealing Tape

- TECBLAST test analysis software

The development of the Minneapolis Duct Blaster has revolutionized performance testing of forced air distribution systems for builders, HVAC contractors, and in a variety of utility programs.

The Duct Blaster is also used for code compliance for total duct leakage and duct leakage to the outside as in IECC 2009 and 2012.

The Minneapolis Duct Blaster is a calibrated air flow measurement system designed to test and document the airtightness of forced air duct systems in both houses and light commercial buildings. The Duct Blaster fan is connected directly to the duct system in a house, typically at a central return, or at the air handler cabinet. With the remaining registers and grilles temporarily taped off, duct airtightness is measured by either pressurizing or depressurizing the duct system and precisely measuring the fan flow and duct pressure. Duct airtightness measurements are used to diagnose and demonstrate leakage problems, estimate efficiency losses from duct leakage, and certify compliance with duct leakage standards such as California’s Title 24 Building Energy Efficiency Standards.

The lightweight Duct Blaster fan weighs just 7 pounds, but delivers enough air flow (an amazing 1,500 CFM) to test the leakiest duct systems. Provices quick and accurate airtightness measurements from 10 – 1,500 CFM. Compatible for both pressurization and depressurization testing. The Duct Blaster can be easily used in new construction applications where a Blower Door can’t be used (e.g. before sheet rock is installed).

Minneapolis Duct Blaster® System (with DG-700)

(Please note that the DG-700 Pressure and Flow Gauge has been discontinued as of November 1, 2017. We will continue to recalibrate the DG-700. We expect to continue to repair the DG-700 for at least 5 years. All systems now come with a DG-1000 Pressure and Flow Gauge.)

System Includes

- Series B Duct Blaster® Fan

- DG-700 Pressure and Flow Gauge (10 – 1,500 CFM)

- Duct Blaster fan speed controller

- Three flow rings (optional Ring 4)

- Twelve feet of 10″ diameter flex duct

- Padded nylon carrying case

- Static pressure probe

- Sample roll of Premium DuctMask Temporary Register Sealing Tape

- TECBLAST test analysis software

The development of the Minneapolis Duct Blaster has revolutionized performance testing of forced air distribution systems for builders, HVAC contractors, and in a variety of utility programs.

The Duct Blaster is also used for code compliance for total duct leakage and duct leakage to the outside as in IECC 2009 and 2012.

The Minneapolis Duct Blaster is a calibrated air flow measurement system designed to test and document the airtightness of forced air duct systems in both houses and light commercial buildings. The Duct Blaster fan is connected directly to the duct system in a house, typically at a central return, or at the air handler cabinet. With the remaining registers and grilles temporarily taped off, duct airtightness is measured by either pressurizing or depressurizing the duct system and precisely measuring the fan flow and duct pressure. Duct airtightness measurements are used to diagnose and demonstrate leakage problems, estimate efficiency losses from duct leakage, and certify compliance with duct leakage standards such as California’s Title 24 Building Energy Efficiency Standards.

The lightweight Duct Blaster fan weighs just 7 pounds, but delivers enough air flow (an amazing 1,500 CFM) to test the leakiest duct systems. Provices quick and accurate airtightness measurements from 10 – 1,500 CFM. Compatible for both pressurization and depressurization testing. The Duct Blaster can be easily used in new construction applications where a Blower Door can’t be used (e.g. before sheet rock is installed).