Why is measuring air flow important?

Heating, Ventilating and Air Conditioning Systems (HVAC) depend on ductwork to deliver air from the air handler (usually part of a furnace or air conditioner) to individual rooms to provide comfort.

The delivery depends, among other things, on duct sizing, construction and leakage. Measuring the air flow at each supply register will provide a way for the HVAC Contractor to determine if the system is supplying the proper flow of air into a given space. The same is true for return air.

There are several characteristics of residential HVAC systems that make it difficult to measure residential register flows accurately with traditional flow capture devices. One is that the flow exits the registers in a small diameter jet that can partially miss the flow sensors in a larger flow capture hood. In addition, the duct construction, especially the short boots and short radius turns, cause large variations in velocity within this jet, making it more difficult to sense an average velocity in the jet. Using the Duct Blaster as a Powered Flow Hood helps solve these problems.

As the ASHRAE Standard 62.2 becomes more widely adopted, measuring accurate airflow from exhaust fans has become more important. Also, accurately measuring exhaust fan airflow will confirm that the fan is preforming to its rated flow and can aid in diagnosing depressurization problems in a home.

Using the Duct Blaster® as a Powered Flow Hood is a four-step process

Using the Duct Blaster® as a Powered Flow Hood is a four-step process

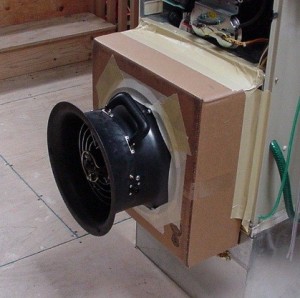

- Step 1: Construct a flow box to seal around the supply register or exhaust fan. One easy option is to use a cardboard box with rough dimensions which are at least 2 times the register dimensions, and the depth of the box should be at least the average of the two opening dimensions.

- Step 2: Install Flow Box to the end of the Duct Blaster Flex and turn on the air handler or exhaust fan.

- Step 3: Turn on Duct Blaster fan to zero out the pressure in the box.

- Step 4: Measure the air flow through the Duct Blaster fan

- The procedure listed above is over simplified. You should refer to Chapter 13 of the Duct Blaster Manual for detailed instructions.

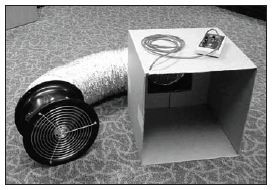

The FlowBlaster® accessory for the Duct Blaster fan (TEC discontinued sales of the FlowBlaster effective January 3, 2017)

Commercial Test and Balance Engineers have used devices called capture hoods to measure flow through large registers for many years. The basic idea is to place a hood, usually of fabric around the opening so that no air leaks out. The hood is connected to a measuring section where the air flow is directed over a grid or set of tubes that sample the flow. This flow is then measured by an instrument that converts the sampled value into CFM. This works with well-constructed ductwork.

Commercial Test and Balance Engineers have used devices called capture hoods to measure flow through large registers for many years. The basic idea is to place a hood, usually of fabric around the opening so that no air leaks out. The hood is connected to a measuring section where the air flow is directed over a grid or set of tubes that sample the flow. This flow is then measured by an instrument that converts the sampled value into CFM. This works with well-constructed ductwork.

There are several characteristics of residential HVAC systems that make it difficult to measure register flows accurately with traditional flow capture devices. The Flow Blaster system is easier to use than the process listed above and also adds additional conditioning so that the flow can be accurately measured, and then compensates for the pressure loss of the flow conditioners by precisely adjusting the speed of the Duct Blaster Fan to remove the pressure loss through the conditioners.

The FlowBlaster was designed specifically for use with residential air flow systems. The FlowBlaster can measure flows down to 10 CFM and up to 300 CFM. The unique, design compensates for variations of construction and is able to measure the flow more accurately than commercial capture hood devices that have been used in the residential market. The Flow Blaster is an accessory that uses the Duct Blaster fan and DG-700 to convert the fan to a powered flow hood. Instead of using the standard fan controller, it uses a battery powered controller that gives you extended flexibility. The system includes handles that will connect to any Duct Blaster fan and can be left attached to the fan.

The air flow rate through residential air handlers is an important variable in estimating and optimizing the performance of heat pumps, air conditioners and furnaces. Numerous field studies of installed heating and cooling systems around the United States have found that insufficient air flow across the indoor coil is an extremely common problem. Low air flow can lead to decreased heating and cooling system capacity, increased energy use and comfort problems.

The Minneapolis Duct Blaster fan can be used to measure total air flow through an air handler. This involves a 4 step procedure:

- Step 1: Turn on the air handler fan and measure the static pressure in the supply plenum.

- Step 2: Turn off the air handler and connect the Duct Blaster Fan to the duct system so all air moving through the system is going through the Duct Blaster fan.

- Step 2: Turn on the air handler and then turn up the Duct Blaster fan until the static pressure in the supply plenum reaches the Normal System Operating Pressure (NSOP).

- Step 4: Measure the air flow going through the Duct Blaster fan.

The procedure listed above is over simplified. You should refer to Chapter 13 of the Duct Blaster Manual for detailed instructions.