Buildings with natural draft combustion appliances should be routinely tested to ensure that the spillage of combustion products into the building is unlikely. Combustion safety testing is critical because of the potential for severe health effects from improperly venting appliances, including carbon monoxide poisoning.

Spillage of combustion products into the building can be caused by a variety of conditions including:

- Blocked or partially blocked chimneys, vents, or vent connectors.

- Improper equipment installation.

- Cracked heat exchangers.

- Leaks in the venting system (disconnected flue pipes, open cleanest door etc.).

- Low vent temperatures.

- Combustion appliance zone depressurization. As buildings are made tighter, it becomes easier for exhaust fans and forced air system imbalances to create potentially hazardous depressurization conditions.

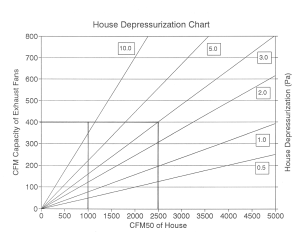

Many cases of improperly venting combustion appliances have been related to depressurization (or negative pressures) in the room that contains the combustion appliance. Depressurization can be caused by exhaust fans, dryers, imbalanced forced air distribution systems and forced air system duct leakage. As buildings (or combustion appliance rooms) are made tighter, these problems can be made worse, although very leaky buildings can also have venting problems related to depressurization. Figure 5 below estimates the amount of depressurization that can be caused by various exhaust fan flows. For example, from Figure 5 we can see that a 400 cfm exhaust fan will depressurize a 2,500 CFM50 building (or room) to approximately 3 Pascals. That same 400 cfm fan would produce over 10 Pascals of depressurization in a 1,000 CFM50 building.

The presence of code approved combustion air intakes does not ensure that venting problems will not occur. Significant combustion room depressurization is frequently found even after code approved combustion air intakes have been installed. Passive combustion room air intakes typically do not provide sufficient airflow to relieve negative pressures caused by distribution imbalances, duct leakage, or large exhaust appliances. For example, a typical 6″ passive inlet can at best supply only about 50 cfm at a 5 Pa negative building pressure. And because passive air intakes are often poorly installed (i.e. many sharp bends, long runs), they typically provide much lower flows than designed. Building codes typically give little or no guidance on how one would design a combustion air opening when competing exhaust appliances are present (the 2000 Minnesota Energy Code is the only code we are aware of to give such guidance).

The only way to be reasonably sure that venting problems will not occur in a building is to perform combustion safety tests. Described below is a test procedure designed to locate existing or potential combustion safety problems in buildings.

If combustion safety problems are found, tenants and building owners should be notified immediately and steps taken to correct the problem including notifying a professional heating contractor if basic remedial actions are not available. Remember, the presence of elevated levels of carbon monoxide in ambient building air or in combustion products is a potentially life threatening situation. Building or duct sealing work should not be undertaken until existing combustion safety problems are resolved, or unless air sealing is itself being used as a remedial action.

This chart can be used to estimate the amount of house depressurization caused by operating exhaust fans. To use the chart, find the intersection between the airtightness (CFM50) of the house and the cfm capacity of the exhaust fans in question. The amount of depressurization caused by the fan(s) is read off the diagonal house depressurzation lines. For example, a 400 cfm kitchen range hood operating in a house with an airtightness level of 2,500 CFM50 would depressurize the house by approximately 3 Pa relative to the outside. This same fan operating in a 1,000 CFM50 house would produce over 10Pa of depressurization. NOTE: This chart was generated by assuming that all houses have a “House Leakage Curve” with an exponent (or slope) of n = 0.65.